Solution.

Cassettes and Screen Characteristics

An intensifying screen is a flat surface that is coated with phosphors. The phosphors fluoresce by illumination to when exposed to the x-rays. The intensifying screens works only if wen x-ray energy is converted into light energy. The phosphors absorb the x-ray light energy and consequently emit the energy in form of light. On the other hand, cassettes are function as a protector to the film from exposure to light during use. Additionally, the cassettes’ rigid property protects the delicate film from scratching or bending during utilization.

Furthermore, they contain intensifying screens, which are kept in close contact with the film during exposure to x-ray light. Cassettes have the exposure side and the access side. The access side is referred to as the “ID blocker” made of radiolucent material, a substance that the x-ray beam can penetrate easily. This material can be made of a light metal alloy or plastic made of durable resin. The back side of the cassette consists of plastic or metal froth. The purpose of the layer is to prevent the backscatter radiation from the cassette tray back that is directed back towards the film. Backscatter radiation can cause a fog if it is not absorbed by the lead foil coating.

Screen Construction and Speed

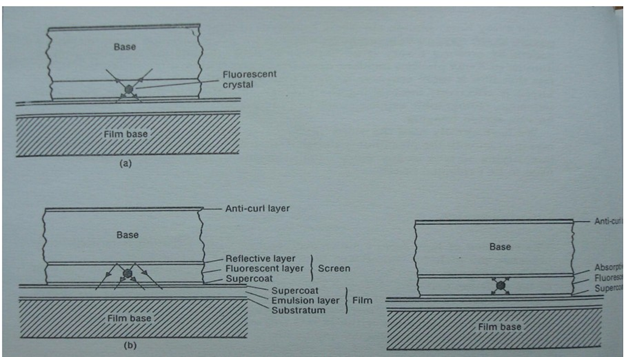

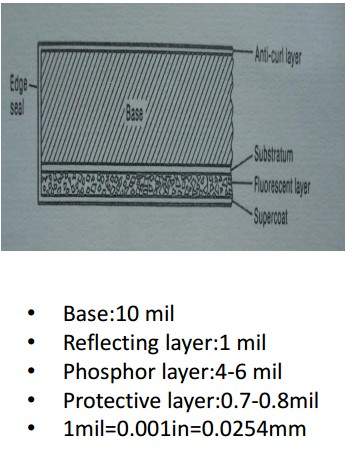

The arrangement of the intensifying screen consists of a base that either made of a polyester plastic or a high grade cardboard that provides a plane, strong and supple sustenance. Additionally, the material is chemically inactive, resists moisture, does not discolor and is consistently radioparent. It also has the substratum layer that can either be reflective or absorptive. Lastly, it has a phosphor layer and a supercoat (See appendix 1). Screen speed is the efficacy of a screen in converting x-rays to light energy. A screen with a greater efficacy requires a minimal exposure. The standard screen is designed as a speed of class 100 against measurement of the speeds of screen. A screen with a speed class of 200 is twice as fast as a screen with a speed class of 100. Archetypal speed classes are 8000, 6000, 400, 200, 100, and 50. When the phosphor absorbs appropriate energy, the crystal will glow irrespective of the portion that was exposed. As a result, the exposure area on the film has a bigger size than the original area. This is the reason why utilization of intensifying screens producing images less defined than images produced by direct exposure to x-rays. On the other hand large crystals and thick layer produce more film exposure given a greater speed but provides a less radiographic resolution through the process called structural mottle. Appendix 2 clearly depicts the processes involved in screen construction

Screen types are designed on the basis of either enhancing speed or detail (resolution), the rapid or regular designs include the rare earth phosphorous that has moderately sized crystals, medium layer thickness and a speed class of 200-800. Also there is the rare earth phosphorous that has small crystals, thick-layered, non-reflective and a speed class of 50-100.

References

Carlton, R. R., & Adler, A. M. (2012). Principles of radiographic imaging: an art and a science. New York: Cengage Learning.

Jenkins, D. J. (2012). Radiographic photography and imaging processes. New York : Springer Science & Business Media.

Appendices

Appendix 1

Appendix 2