Clinical Supply Chain Improvement at Yuma Regional Medical Centre

Instructions:

Phase I: Improvement Opportunity

Write 500-750 words on improvement opportunity in your sphere of influence. Address each of the following sections:

Quality Tool Analysis

Identify your problem statement and complete a root-cause analysis. Identify which quality tools you used to identify and vet the problem. Explain the quantitative and qualitative tools you used and provide a summary of how you arrived at your problem.

Stakeholder Analysis

Complete the interactive “Stakeholder Analysis: Winning Support for Your Projects,” located on the Mind Tools website. In Step 2, select the “Interactive Screen App” hyperlink. Provide a Power/Interest Grid of your completed chart (using either a picture format or a handwritten document). In addition, provide a summary that includes considerations for all stakeholders. These considerations will form your communication plan in Part II.

The “Winning Support for your Project” document is attached.

Prepare this assignment according to the guidelines found in the APA Style Guide, located in the Student Success Center

Phase II: Planning and Implementation

In Phase II of the Process Improvement Project you will be creating a project timeline to help you implement the proposed solution to the problem statement defined in Phase I. As a project leader, you will need to consider several things before you start the project. The project leader must preplan, plan, and kickoff the project.

Planning of the Project

As the project leader, write 500-750 words that address these items:

1. Identify which methodologies and strategies you will implement to meet your goals. Provide rationale for why you did not select some of the other methodologies and strategies.

2. Which business functions will be impacted by your action plan? What tactics will you use to manage implementation across business functions? What can you do to enhance collaboration/cross-functionality to ensure the success of your plan?

3. Timeline: Create a timeline to implement the proposed improvement to the problem and identify the critical path components.

4. Communication plan: Using your completed quality tools analysis and stakeholder analysis, create a communication plan for disseminating your action plan to all of the stakeholders. Which strategies do you plan to utilize and why? Your plan should demonstrate how you plan to use formal and informal communication channels to implement the plan. In addition, explain how the communication plan addresses what you are hoping to achieve with your goal.

Project Kickoff and Implementation of the Project

Successfully improving the value chain requires the willingness of required stakeholders to participate. Imagine you are presenting your project plan in a meeting to all the essential stakeholders for approval. Effective oral communication is essential in the business setting so you will need to present your project plan logically and comprehensively to the stakeholders.

• Create a PowerPoint presentation (7-10 slides) specifying the problem statement, stakeholders, proposed solution, timeline, and communication plan to implement the project.

• Write a script presenting the plan that allows you to post your video. Be sure to address the “why” and “how” in your narrative. Imagine you are presenting your strategic plan in a meeting with your superior and other essential stakeholders for approval.

Phase III: Evaluation

In the final step for your plan, state in 250-300 words the metrics you will use to determine project implementation success. Please justify why you have selected those metrics. Include specific metrics that will be used to evaluate the success of the implementation. How long will the project team monitor project implementation?

This assignment uses a rubric. Please review the rubric prior to beginning the assignment to become familiar with the expectations for successful completion.

Solution

Clinical Supply Chain Improvement at Yuma Regional Medical Centre

Background

Simple surgical processes can be completed in less than an hour. For instance, a laparoscopic cholecystectomy procedure at Yuma Regional Medical Center takes less than forty minutes to complete. But when the circulating nurses in the operating room must leave in search of a missing specimen like the endo retrieval bag because of a labelling error, things can easily change from a safe surgical process to a life threatening situation. If there are no other emergency response specimens in the operating room, calls have to made, other clinicians removed from their work stations to help retrieve the right endo retrieval bag. Eventually, even if the situation is fully managed without any complication to the patient, the schedule is affected and other surgeries have to be rescheduled. The staff members are likely to lose confidence in the supply chain while some clinicians may take advantage and take stockpiling supplies away from the hospital causing shortages. The surgical team at Yuma Regional Medical Centre is likely to find itself in such a situation because of the time and effort it takes to overhaul the current supply chain system. Whatever the reason, implementing change in every work environment is a daunting experience but can be implemented as a small procedure and increased gradually. A single supply chain aspect like the procedure card review can improve surgical services delivery both from patient outcome and departmental spending.

Problem Analysis

Successful clinical supply chain improvement projects improve service delivery and supports better patient care. By developing, improving, and implementing this supply chain process, the hospital can reduce on operating costs besides threats to the patients’ life. Currently, the hospitals supply chain suffers from;

- Non-standardized manual supply management process

- Lack of reliable information to support metric analysis for the supply chain activities

- Insufficient communication between the surgical team in the operating room, the medical reprocessing unit, and the material management group

- Excessive, duplicated, and obsolete inventories

- Outdated pick-lists and surgical supply procedure cards

Application and review procedure

This clinical supply chain process improvement procedure is primarily based on the business process of providing medical products to the surgical suites and core operating room sterile. While identifying the above problems in the hospital’s supply chain, a review of the program outcomes was done. It was noticed that the implementation of the supply chain procedure cards will demonstrate an effective communication plan and a better return on investment for the hospital. It is anticipated that there will be an increase in the patients’ safety, staff satisfaction, and a reduction in the product related errors.

Both qualitative and quantitative methodologies were used to synthesize the results. Qualitatively, most of the models were developed and implemented without reference models and a proper formulation of the products supply cycle. The management was basically convinced that the clinical supply chain would be a success venture in the business environments as it has been in other hospitals. Due to lack of proper monitoring mechanisms, no procedures were followed to ensure correct parameters were indicated on the specimen labels and sizes. This made it hard for nurses and surgical teams to ascertain and confirm that they were issued with the correct or wrong specimens (Pinna, Paolo &Marras, 2015). Lack of awareness among the nurses as obtained during the interviews orchestrated the re-examination of supply process.

Quantitatively, comparisons were made within the data limits obtained from the questionnaire responses. In the comparison, a limit between the number of erroneous supplies and the time taken to correct the supply error was evaluated against the number of errors done in hospitals using procedure cards in the supply chain. Since the research was done based on research reviews, the estimate of the errors before interventions was defined according to available historical data on the performance of similar projects in other hospitals(Pinna, Paolo &Marras, 2015). The levels of attaining the objectives of the investors was evaluated against the final assessment of the performance of the systems. The assessment confirmed that the supply management personnel were unaware of the problem and how to mitigate it. Likewise, the surgical team and the nurses were not aware of any other ways of mitigating the problems and resolved to holding-up surgeries until the correct specimens are obtained.

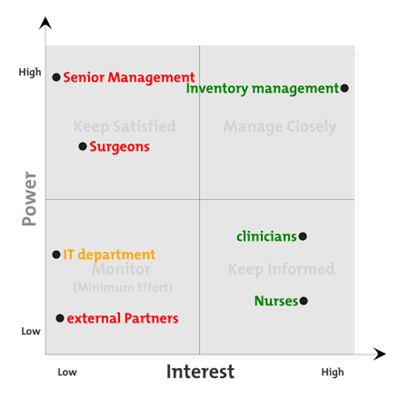

Stakeholder Analysis

Research on high performance enterprises demonstrate that regular and continuous improvement in customer satisfactions leads to a better achievement of any ongoing improvement targets in a planning process (Thompson, 2016). This can only be achieved by a proper understanding of the various stake holders in the system. Figure 1 highlights some of the immediate notable stakeholders in the supply chain and the level of effect they have on the project.

Figure 1. Adopted from Thompson (2016).

Planning and Implementation

When planning for or implementing a project in the health sector, it is important to consider a buy-in option for the division and departmental heads (Jacobs& Chase, 2014). This is important because they help individual surgeons in moving towards the more generic pick lists using procedure cards. Across the United States, many developed hospitals have succeeded in minimizing the differences in pick lists although it took the efforts of strong leaders. For the success of the project, educating the surgeons on the importance of the changes is key. The project will be planned and implemented in four stages.

- Formation of the project team

Projects involve processes and tasks that need to be developed to completion by different partners within the organization. As a result, a clear and concise steering committee managed by the project manager will oversee the project process. The team’s objective will be the use of combined expertise and their knowledge of the supply chain requirements to investigate the opportunities of standardization available. This will be done with input from the surgical team and the nurses. Representatives from various departments will be represented as follows in the committee;

- The clinical department shall provide a clinical leader, a service nurse, clinical supply coordinator and an administrator

- The business functions shall provide a booking clerk, perioperative manager, procurement officer, and a finance/ administrative officer.

- External partners will be obtained from a shared service organization.

- Identification of the stakeholders

Knowing your stake holders as a project manager is key to the successful implementation and acceptance of a project. In designing the procedure card solution, understanding the roles that every stakeholder will play shall not only function well but make the project universally accepted (Cheng, 2008). Although some of the stakeholders will be on the project team, it shall be important to clarify the roles of each as below;

- Senior management – shall provide all support, approval, and resolutions to conflicts besides claiming insights on the benefits of the improvements.

- Surgeons – shall provide buy-in support after realizing the effectiveness of the project to their service delivery

- Clinicians – shall champion for change because they are the immediate beneficiaries of the project

- IT department – shall provide knowledge support and automation of the system

- Inventory management – shall support the optimization of the purchases, finance and service provision

- External partners – shall provide third party support and guide to shared services.

- Process project plan

Ensuring a project success is an important aspect especially when improving on an already existing service or process. Failure may lead to catastrophic effects and lack of confidence in any other future changes from the staff. As such, the project team will agree that;

- The senior management of the hospital must be involved in the process and where possible minimize their preferences to drive standardization

- Surgeons be made to support the initiative fully

- The resource nurse on the project tem be the agent of change

- A criteria be developed by the inventory management using their expertise in the area categorizing, in-stock, non-stock and products on consignment based on their history and usage.

- Product evaluation committee be established and be fully incorporated in the process

- “Just in case” behavior be minimized by all the members and work in collective responsibility

- Establishing a starting point

To effectively ascertain the impact of the improvements a collective baseline metrics will help understand the situation. As noted by Cheng (2008), the following metrics shall guide the project improvements;

- Number of erroneous supplies in a month

- Number of case delays reported

- Amount of nurses called or leaving station to correct the supply

- Amount of time spent during the correction procedure

- Value of the operating room inventory

- Case chart item utilization

- Number of clean sheets monthly

- The measure of surgical cases

- Number of common and unique procedure cards opened

Affected business functions

To provide an understanding and effective rollover of the project, the management functions of the hospital shall be halted to allow for the implementation of new procedure cards as opposed to the current pick-up lists. The data optimization functions will be affected to incorporate the management of medical and surgical products in their system. The inventory shall be required to provide a product replenishment criteria alongside new physical storage space. The finance will be required to allocate funds meant for other projects deemed not of agency to the project. Other normal functions at the hospital will continue as usual until the final rollover of the system.

Project timeline

The project is expected to last for 180 days spread over as follows in table 1;

Table 1; project timeline

| Activity | Responsibility | Period (days) |

| Service improvement launch | Management | 180 |

| Survey / data collection | Project team & project manager | 15 |

| Data analysis | Project team & project manager | 30 |

| Report generation | Project manager | 7 |

| Shareholder identification | Management & project manager | 21 |

| Identification of Client priorities | Project team & project manager | 7 |

| Service improvement plan | Management & project manager | 7 |

| Prototype design | Project team & technical team | 65 |

| Design implementation | Programmers | 14 |

| Training | Programmers | 7 |

| Markup | Project team | 7 |

| Rollout | All | 2 |

Communication plan

Collaboration is very important for the successful upgrade project. The following attributes shall guide the connection between the members of the staff.

| Key Stakeholders | Communication items |

| Senior management | Issue management and resolution support Project the status of the project Chair steering committee meetings |

| Operating room/ Surgical team management | Communicate accomplishmentIdentify and resolve any arising implementation issuesMonitor the support on the project objectives |

| Clinicians | Create forums for inputs and feedback on the project team’s input and other ad hoc work teams |

| Surgeons | Prepare status update reports |

| Inventory management | Create forums for inputs and feedback on the purchases made and shared among the organization |

| Suppliers | Identify the required surgical supplies and communicate any replenishment changes |

| IT management | Ensure system requirements are captured for the projects tasks |

| Finance management | Engage in business plan development for the project to provide costing and budget forecasts |

| Bio Medics | Provide data for the required inputs |

Project Evaluation

After project implementation it is critical to the project manager to carry out analysis of the new inventory system in the supply chain on periodic basis. According to Levy (2010), this is done in due observation of;

- The quality of service and satisfaction to the clients in this case both the patients and the surgeons

- The staff compliance with the new ordering parameters

- The efficiency and objectives achieved

Based on the above mentioned criteria, the project shall be evaluated as follows;

| Measure | Data required | Collection (measured on the data obtained) |

| Impact on clinical labor | Nursing hours spent to correct specimen | |

| Impact on on-hand inventory | On-hand inventory audit reports | |

| Impact on inventory obsolescence | Number of expired supplies | |

| Impact on the proportion of rush orders | Number of rush orders against the replenished orders | |

| Inventory turnovers | Total inventory values to the operating room | |

| Inventory turnovers by category | Total inventory divided by the annual supply by category to the operating room | |

| Level of improvement in patient service delivery, stock-outs, and surgical suite delays | Number of delays Fill rates to the end users Stock-outs at every cart level Number of stock out Customer satisfaction |

Conclusion

Successful supply and replenishment of surgical products at Yuma Medical Regional Center’s clinical service involves multiple functions. The efforts employed by various departments are key to the achievements of the project’s goals as well as the support needed by the project manager. A review of the existing process both quantitatively and qualitatively provided the much needed data to structure the new project improvement guidelines. Based on the experience the staff are expected to gain from the new supply chain modalities, it is expected that the hospital shall save on time, reduce errors during surgeries and implement experience based improvements in the operating room.

References

Cheng, S.H. (2008). An engineering approach to improving hospital supply chains. Retrieved from https://dspace.mit.edu/bitstream/handle/1721.1/44928/310353136-MIT.pdf?sequence=2

Jacobs, R., &Chase, B., (2014). Operations and supply chain management, 14thedn. New York,

NY, McGraw-Hill Publishers.

Pinna, R., Paolo, P., &Marras, F. (2015). Emerging trends in healthcare supply chainmanagement

— an Italian experience. World’s largest Science,Technology & MedicineOpen Access book publisher. Retrieved from http://cdn.intechopen.com/pdfs-wm/47830.pdf

Thompson, R. (2016). Stakeholder analysis: winning support for your projects. Retrieved from https://www.mindtools.com/pages/article/newPPM_07.htm#Interactive

Levy, S. (2010). Construction process planning and management: an owner’s guide to successful

projects. Burlington: Elsevier Inc.