Effective Supplier Evaluations

Instructions:-

Resources: Internet, University Library, Textbook

Your Supply Chain Manager has assigned you the responsibility of developing a new Supplier Evaluation process for your company. Your company has experienced an unfavorable trend in low productivity as a result of component availability, re-working of product, and increased inventory levels of nonconforming material. Your company cannot seem to effectively measure supplier performance because it doesn’t know which metrics to implement that will drive the right changes.

To make matters worse, your company is working to become ISO9001 certified. ISO9001:2008 requires supplier evaluation and data analyses so this needs to be considered when developing the Supplier Evaluation process.

Identify the top ten supplier performance criteria you want to use in the evaluation process

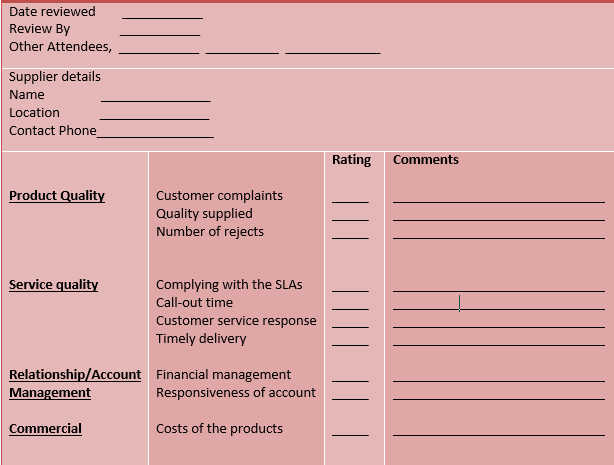

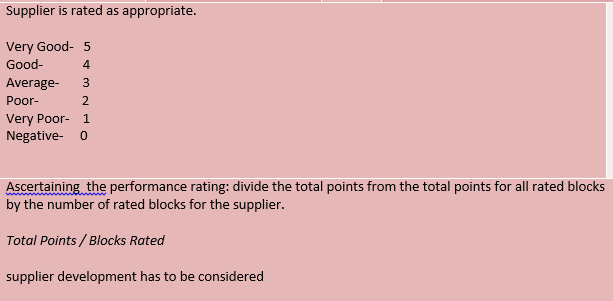

Create a Supplier Evaluation template with the key criteria data you want to analyze.

Write a 1,050- to 1,400-word proposal that includes:

•Purpose of a Supplier Evaluation process

•Example of template

•Implementation plan: include who is responsible for collecting data and how you will determine which suppliers will be measured.

•Supplier communication plan to inform selected suppliers of this new process

•Explain how data will be used to drive supplier performance improvements.

Format the paper according to APA standards.

Click the Assignment Files tab to submit your assignment

Solution

Effective Supplier Evaluations

The company needs certification from national and international bodies so that it will be in a position to check the quality of its supplier. The most widely and internationally respected of the certifications is the International Organization for Standardization 9001. The ISO 9001 will allow the organization to use the set of quality standards recognized globally (Psomas, Pantouvakis, & Kafetzopoulos, 2013). The certification aims to promote international trade by providing a common set of standards accepted and respected by all companies globally. However, before the organization can attain the certification, it must meet a set of conditions. First, the company should clearly state its objectives and the benefits it intends to gain upon achieving the ISO 9001 Certification. The company should also have a well-documented Quality Management System alongside the company policies and procedures (Psomas, Pantouvakis, & Kafetzopoulos, 2013). In the long run, all the staff must familiarize with the roles they should play to earn ISO 9001 Certification.

Supplier performance criteria

There exist several key factors that may be used in assessing the performance of a supplier and which are also used as the yardstick to determine the effectiveness of supplier activities for particular situations (Sarkar & Mohapatra, 2006). The firm should, therefore, focus on the attributes it finds to be the most important. While some of the attributes are measurable, others are difficult to measure. The majority of organizations measures use the following areas while measuring supplier performance:

- The quality of supplied Product

- The accuracy of delivery through ascertaining the number of incoming rejects

- Number of complaints from the customer

- Service Quality complying with the SLAs

- Call-out time

- Time is taken for Customer service response

- Timely delivery performance on the agreed delivery lead time

- Financial management aspects

- Responsiveness of account management by the supplier

- Costs of the products

Companies are also advised to consider ‘soft’ issues that are also frequently encountered. These include ethical issues, professional relationships, sustainability issues, and innovation (Sarkar & Mohapatra, 2006). These measures are expected to reflect the agreements agreed upon when setting the contract. It is, therefore, necessary for both parties to be specific in their commitment to continuously improving from the onset. It would be considered unfair on the supplier’s side if suddenly a new range of measures were introduced long after the contract is underway unless both parties settled on a contract variation framework giving them the room for introducing such measures with the intention of meeting the aspirations all parties.

The Supplier Evaluation process

An effective monitoring of the supplier performance should give the company an early warning whenever the supplier shows signs of having difficulty in coming to terms with the contract or when they apparently fail to meet the set performance standards (Sarkar & Mohapatra, 2006). Immediate action must, therefore, be taken if it is revealed that supplier performance is below the agreed upon standards during the setting of the contract. Such an early intervention can help in preventing a potential problem from escalating into a dispute. It further protects the value for money. Suppliers need to be informed of the shortcomings in their performance as soon as they are spotted. In cases of a serious or repeating problem, the suppliers then have to be formally warned through writing that their performance level does not meet the expectations of the company. An additional explanation should accompany the warning together with the recommendations for change that would then meet the performance expectations. The situation will then enable the company to identify and address performance issues within its supply chain. The providers will also get the opportunity to improve their performance to acceptable levels before a serious action may be taken against them.

Implementation plan

The Purchasing and Supply Management professionals are in charge of all the organization’s supply activities. They implement the appropriate procedures, obtain data about supplier information, and allocate the respective supply duties accordingly. Furthermore, P&SM sector is proactive in making recommendations to the Board on the appropriate policy to be used in the supply chain sector.

The suppliers dealing with high-value and high-risk products need to be closely monitored for their performance. It is where mush resources should be directed. Monitoring may involve regular meetings that aim to discuss performance, resolved issues and whether the targets set are appropriate. The failure of the critical suppliers may lead to significant losses for the company it is, therefore, important to foresee that within the contract are suitably clauses and contingency plans of action. The P&SM department should hold frequent feedback meetings within the premises of the suppliers. It will help them to assess the levels of efficiency on the suppliers’ locality. However, the case may not apply for outsourced services, like cleaning and catering. Meeting in the service sector is held in areas that facilitate inspection. The approach is enough to ensure that the senior management on the contractor’s side is present.

Supplier communication plan

On the other hand, suppliers also need to be informed from the outset that in the course of fulfilling their side of the contract, their performance will consistently be assessed and record taken. They should, therefore, be briefed on the criteria to be used in advance. These should include how the measuring will be undertaken, how the assessments will be recorded and the people that will access the performance evaluation results (Sarkar & Mohapatra, 2006). The company may choose to give the suppliers the opportunities to participate in developing and implementing the performance management criteria. All these have to be established before the signing of the contract. Frequent consultation with the suppliers on performance issues facilitates the effective monitoring and management process.

Uses of the collected data

A sound and successful performance management process gives rise to organized records. The records may be used to verify performance and act as a good reference point whenever there is a need for a contract extension or renewal (Sarkar & Mohapatra, 2006). In some cases, these records are used to justify the termination of a contract as a result of failure on the supplier’s side to perform as per the expected standards. The records provide critical information that influences decisions on future procurement. However, the company must practice due regard of the supplier’s right, fair process and comply with the Competition and Consumer Act. Information on supplier performance deserves to be handled sensitively so that no disputes would arise over its collection and use.

References

Psomas, E. L., Pantouvakis, A., & Kafetzopoulos, D. P. (2013). The impact of ISO 9001 effectiveness on the performance of service companies. Managing Service Quality: An International Journal, 23(2), 149-164.

Sarkar, A., & Mohapatra, P. K. (2006). Evaluation of supplier capability and performance: A method for supply base reduction. Journal of Purchasing and Supply Management, 12(3), 148-163.